| GB | JIS | ASTM | UNS | KS | W.Nr | |||||||

| 022Cr19Ni13Mo3 | SUS317L | AISI317L | S31703 | STS317L | 1.4438 | |||||||

| Surface: | Mill;HL;Polish;Mirror;NO.4;Pvd….. | |||||||||||

| Tchnology: | Cold rolled;Hot rolled | |||||||||||

| MOQ: | 200KG | |||||||||||

| Payment Term: | T/T;L/C;WesternUnion;Paypal | |||||||||||

| Delivery Time: | 7-15days upon receipt of the deposit | |||||||||||

| Package: | Standard Expot Packing or As Customers Requirement | |||||||||||

| Processing form:

|

|

|

|

|

|

|||||||

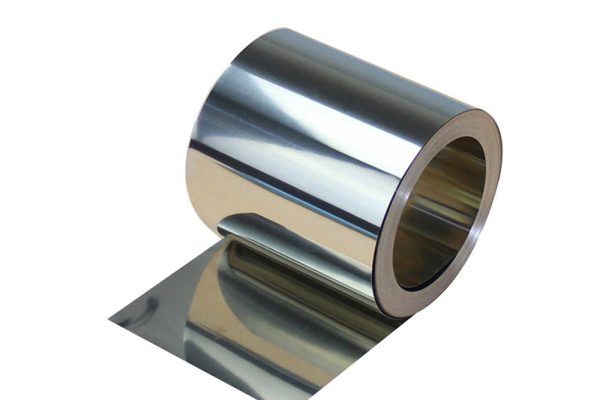

AISI 317L stainless steel coil & strip

Product Description:

Product Details:AISI 317L Stainless Steel Coil & Strip

Width: 1000mm/1219/mm/1500mm/1800mm/2000mm/Customizable

Length: COIL & STRIP

Surface:2B/NO.1/BA

SGS test report available

Stainless Steel Details

chemical composition

| C | Si | Mn | P | S | Ni | Cr | Mo | Ti |

| 0.00-

0.08 |

0.00-

1.00 |

0.00-

2.00 |

0.00-

0.045 |

0.00-

0.03 |

10.00-

14.00 |

16.00-

19.00 |

1.80-

2.500 |

0.20-

0.70 |

Mechanical Property

| T.S(Mpa)≥ | YS(Mpa)≥ | EL(%)≥ | HB |

| 520 | 205 | 40 | 160-180 |

chemical composition

| C | Si | Mn | P | S | Ni | Cr | Mo | Ti |

| 0.00-

0.08 |

0.00-

1.00 |

0.00-

2.00 |

0.00-

0.045 |

0.00-

0.03 |

10.00-

14.00 |

16.00-

19.00 |

1.80-

2.500 |

0.20-

0.70 |

Mechanical Property

| T.S(Mpa)≥ | YS(Mpa)≥ | EL(%)≥ | HB |

| 520 | 205 | 40 | 160-180 |

Stainless Steel Introduce

317L stainless steel is an austenitic stainless steel that contains a low carbon content and higher amounts of molybdenum and nickel compared to 304 stainless steel. The low carbon content of 317L reduces the risk of intergranular corrosion caused by sensitization during welding or high-temperature exposure.

The higher nickel and molybdenum content of 317L provide superior resistance to corrosion in harsh environments, particularly those containing chlorides or other halides. This makes it suitable for use in chemical processing, pulp and paper manufacturing, and oil and gas refining applications.

317L stainless steel offers excellent toughness, strength, and formability, and is easy to fabricate using standard methods. It can be welded using common welding techniques, and is often used to fabricate complex shapes and components.

Some of the key properties of 317L stainless steel include:

Corrosion resistance: 317L offers superior corrosion resistance in harsh environments, particularly those containing chlorides or other halides.

High-temperature resistance: 317L can withstand high temperatures and thermal cycling without losing its corrosion resistance properties.

Strength and toughness: 317L offers good strength and toughness, making it suitable for use in demanding applications.

Fabricability: 317L is easy to fabricate using standard methods, and can be welded using common welding techniques.

Overall, 317L stainless steel is a versatile and reliable material that is well-suited for use in a wide range of applications where superior corrosion resistance and high-temperature performance are required.

American Standard: ASTM A240/A240M-20a

European Standard: EN 10088-2:2005

Japanese Standard: JIS G4304-2005

Chinese Standard: GB/T 3280-2015

Here are some of the most common international standards for 317L stainless steel:

ASTM A240/A240M: Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and for General Applications

ASTM A312/A312M: Standard Specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipes

ASTM A403/A403M: Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings

ASTM A479/A479M: Standard Specification for Stainless Steel Bars and Shapes for Use in Boilers and Other Pressure Vessels

EN 10088-2: Stainless steels – Part 2: Technical delivery conditions for sheet/plate and strip of corrosion resisting steels for general purposes

JIS G4304: Hot-rolled stainless steel plate, sheet and strip

GB/T 3280: Cold rolled stainless steel plate, sheet and strip

WAYEN.M.IND has a 20,000 square meter warehouse in Guangdong, China. The annual inventory of stainless steel plates exceeds 50,000 tons. It has various shearing machines such as 1000mm, 1219mm, 1500mm and so on. Bingjie has various surface treatment equipment, which can process surfaces including NO.4, HL, 8K, 10K, POLISH, MIRROR, PVD, ECHING, EMBOSSED, BEAD BLAST, HOT TRANSFER-WOODED SERIES. It acts as an agent for large Chinese steel mills to produce stainless steel coils. . Partners include POSCO, TISCO, YONGJIN, QSINGSAN, HONGWANG, BAOSTEEL.ECT….

We have passed ISO9001 quality certification, CE, BIS, JIS. We have three departments: factory, trade and foreign export. More than 300 employees. After more than 10 years of accumulated export experience, we have 300 long-term cooperative customers in more than 50 countries around the world. The factory has rich experience in export production, from warehousing, quality inspection, production, re-quality inspection, packaging, loading and transportation . All processes are top quality. It is guaranteed that the stainless steel plates delivered to customers are perfect.

We have passed ISO9001 quality certification, CE, BIS, JIS. We have three departments: factory, trade and foreign export. More than 300 employees. After more than 10 years of accumulated export experience, we have 300 long-term cooperative customers in more than 50 countries around the world. The factory has rich experience in export production, from warehousing, quality inspection, production, re-quality inspection, packaging, loading and transportation . All processes are top quality. It is guaranteed that the stainless steel plates delivered to customers are perfect.

Q1.What are the main products of WAYEN.M.IND?

A1.WAYEN.M.IND’s main products include 201/304/316L/430/310S/2205 and other stainless steel coils and plates, with various styles of etching and embossing, and surface treatments will be customized.

Q2. How do you ensure the quality of your products?

A2. All products must undergo three inspections during the entire manufacturing process, including production, cutting and packaging.

Q3. What is your delivery time and supply capacity?

A3. The delivery time is usually within 15~20 working days, and we can supply about 15,000 tons per month.

Q4. What kind of equipment does your factory have?

A4. Our factory has advanced five-eight-roll rolling and cold rolling upper roll production equipment, as well as advanced processing and testing equipment, making our products higher quality and more efficient.

Q5. How do you handle after-sales services such as complaints and quality issues?

A5. We will have specific colleagues to track each order accordingly and provide professional after-sales service. If any claim occurs, we will assume responsibility and indemnify according to the contract. In order to better serve our customers, we will constantly track customer feedback on our products, this is what differentiates us from other suppliers. We are a customer care business.

Application fields

Compared with 316L, 317L steel has good seawater resistance and SCC resistance, and is used in chemical ships, chemical product Reactors and other chemical equipment that require high corrosion resistance.

Compared with 316L, 317L steel has good seawater resistance and SCC resistance, and is used in chemical ships, chemical product Reactors and other chemical equipment that require high corrosion resistance.