| GRADE | GRADE | GRADE | GRADE | ||||

| AISI 201 | AISI 304 | AISI 316L | AISI 310S | ||||

| Executive standard | ASTM A554 | ||||||

| Surface: | 4K.,6K.,8K.,10K.,12K Double face | ||||||

| Tchnology: | Polished | ||||||

| MOQ: | 200KG | ||||||

| Payment Term: | T/T;L/C;WesternUnion;Paypal | ||||||

| Delivery Time: | 7-15days upon receipt of the deposit | ||||||

| Package: | Standard Expot Packing or As Customers Requirement | ||||||

| Processing form: | Mirror sheet | Mirror plate | Mirror PVD sheet | Mirror etching sheet | Mirror embossed sheet | ||

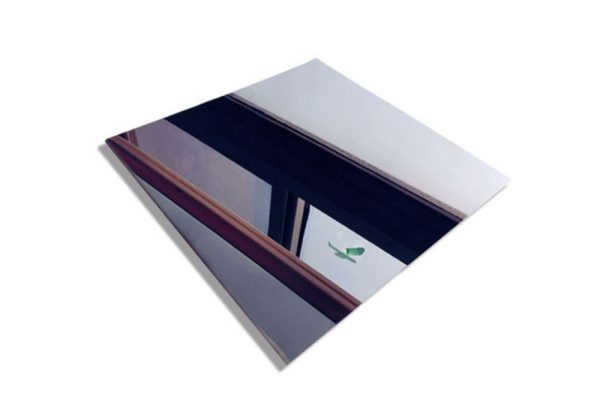

8K Mirror Stainless Steel Sheet

Product Description:

Product Details:Mirror Stainless Steel Sheets

Surface:4K,6K,8K,10K,12K

Width:

1000mm/1219/mm/1500mm/1800mm/2000mm/Customizable

Length:

2000m/2438mm/3000mm/6000mm/10000mm/Customizable

SGS test report available

Stainless Steel Details

Stainless Steel Introduce

Stainless steel mirror panel 8K

The varieties of 8K mirror stainless steel plates are mainly divided into two types: single-sided and double-sided. Luminosity includes 6K, ordinary 8K, precision polished 8K and 10K, etc. Material selection is mainly about selection

Stainless steel 2B and BA panels such as 201, 304, 316 or 430 are used as the base plate. Polishing equipment and abrasive fluid are used to polish the stainless steel plate surface, so that the brightness of the stainless steel plate surface is as clear as a mirror.

The grinding fluid is prepared by mixing water, nitric acid and iron red powder in a certain proportion. The better the proportion is, the better it will be for the quality of the stainless steel mirror panel.

Rough polishing usually uses a grinding wheel. The grinding wheel numbers are arranged from coarse to fine in the order of 80#, 120#, 240#, 320#, 400#, and 600#. This process usually uses clean water for grinding, and generally uses six groups of grinding. The machine is mainly used to remove surface roughness, burrs and blisters.

For fine polishing, you only need to use machine-made wool felt. The higher the density of the material, the better. This process uses water, nitric acid, and iron red powder to grind. Usually ten groups of grinders are used, and there is no corresponding depth. It is mainly to remove the surface oxide layer and blisters. , Coarsely grind the grinding head to increase the brightness.

The washing and drying process is to use clean water to clean. The finer the brush used, the better. The cleaner the water, the cleaner it will be after cleaning. Then use a baking lamp to dry.

Quality inspection refers to checking the photometry, the number of blisters, whether there are peeling lines or scratches, whether the stainless steel plate products are deformed, and whether the grinding head flowers are controlled within a certain range. If any of the above requirements are not met, it can be judged. The quality of this stainless steel product is not up to par.

WAYEN.M.IND has a 20,000 square meter warehouse in Guangdong, China. The annual inventory of stainless steel plates exceeds 50,000 tons. It has various shearing machines such as 1000mm, 1219mm, 1500mm and so on. Bingjie has various surface treatment equipment, which can process surfaces including NO.4, HL, 8K, 10K, POLISH, MIRROR, PVD, ECHING, EMBOSSED, BEAD BLAST, HOT TRANSFER-WOODED SERIES. It acts as an agent for large Chinese steel mills to produce stainless steel coils. . Partners include POSCO, TISCO, YONGJIN, QSINGSAN, HONGWANG, BAOSTEEL.ECT….

We have passed ISO9001 quality certification, CE, BIS, JIS. We have three departments: factory, trade and foreign export. More than 300 employees. After more than 10 years of accumulated export experience, we have 300 long-term cooperative customers in more than 50 countries around the world. The factory has rich experience in export production, from warehousing, quality inspection, production, re-quality inspection, packaging, loading and transportation . All processes are top quality. It is guaranteed that the stainless steel plates delivered to customers are perfect.

Q1.What are the main products of WAYEN.M.IND?

A1.WAYEN.M.IND’s main products include 201/304/316L/430/310S/2205 and other stainless steel coils and plates, with various styles of etching and embossing, and surface treatments will be customized.

Q2. How do you ensure the quality of your products?

A2. All products must undergo three inspections during the entire manufacturing process, including production, cutting and packaging.

Q3. What is your delivery time and supply capacity?

A3. The delivery time is usually within 15~20 working days, and we can supply about 15,000 tons per month.

Q4. What kind of equipment does your factory have?

A4. Our factory has advanced five-eight-roll rolling and cold rolling upper roll production equipment, as well as advanced processing and testing equipment, making our products higher quality and more efficient.

Q5. How do you handle after-sales services such as complaints and quality issues?

A5. We will have specific colleagues to track each order accordingly and provide professional after-sales service. If any claim occurs, we will assume responsibility and indemnify according to the contract. In order to better serve our customers, we will constantly track customer feedback on our products, this is what differentiates us from other suppliers. We are a customer care business.

Application fields

The last step is to apply a protective film to the stainless steel mirror panel that meets the standard and pack it into boxes. The requirement is that the protective film should be applied flatly and no leakage should occur. The uses of 8K stainless steel mirror panels mainly include architectural decoration, stainless steel shower equipment, kitchen and bathroom appliances, elevator decoration, industrial accessories and other decoration fields.

The last step is to apply a protective film to the stainless steel mirror panel that meets the standard and pack it into boxes. The requirement is that the protective film should be applied flatly and no leakage should occur. The uses of 8K stainless steel mirror panels mainly include architectural decoration, stainless steel shower equipment, kitchen and bathroom appliances, elevator decoration, industrial accessories and other decoration fields.