Austenitic stainless steel

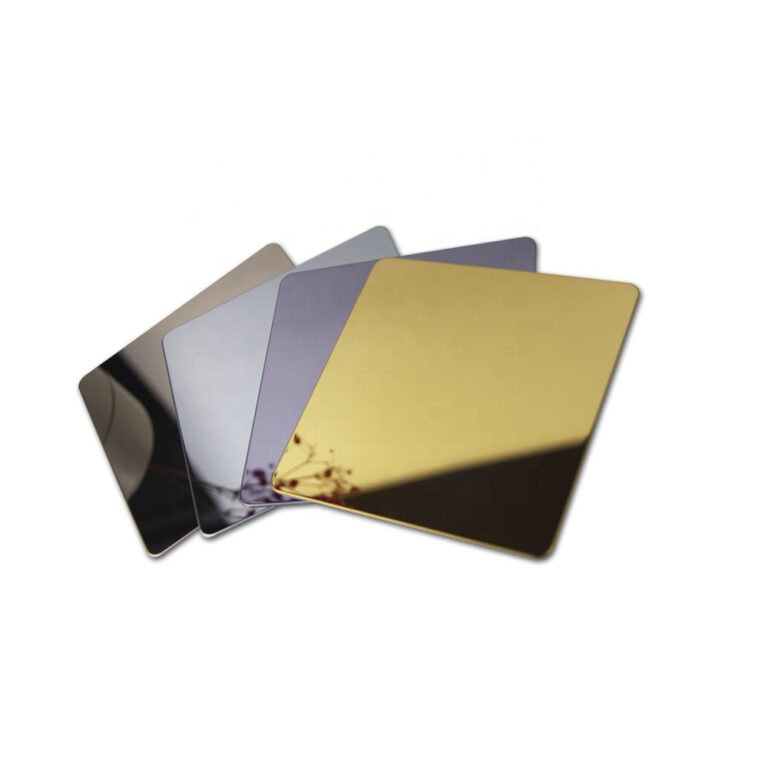

Diverse Surface Treatment

(HL 8K NO.4 PVD...)

Material

(304 304L 316L 321 321S 904L...)

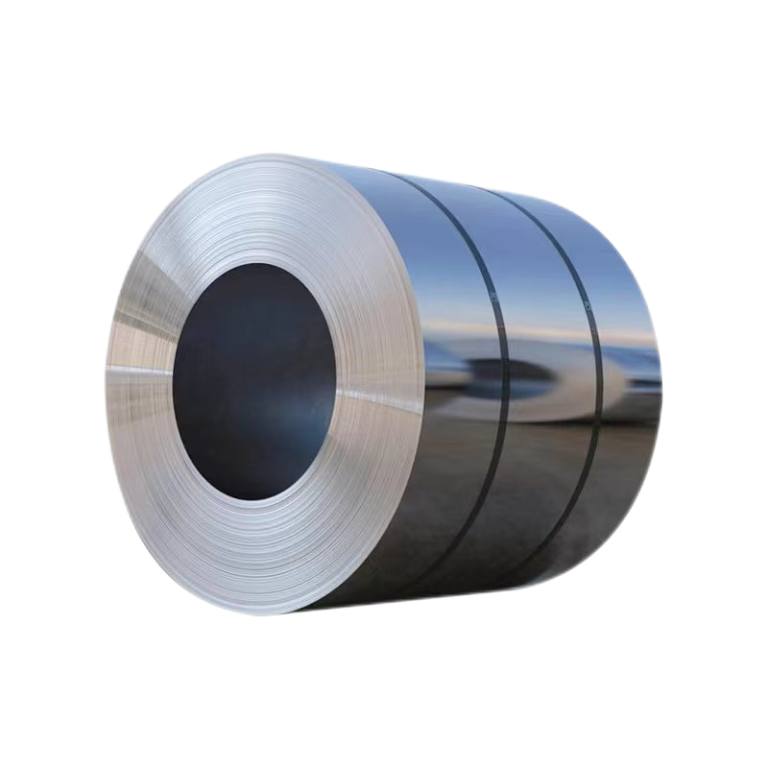

Various Processing Formsy

(Coil、Plate、Tube、Bar)

Maximum Inventory

(The annual inventory exceeds 8000tons)

Most Widely Used

(Architecture Decoration、Commercial Manufacture、Chemical Smelting...)

Numberous Agent Brands

(Hongwang、NISCO、TISCO、POSCO...)

FEATURE PRODUCTS

Incoloy Alloy

Incoloy alloy 825/800H/800HT/800HP/G-3/020/901/902/903/907/908/909/925/926/945/890

Haynes Alloy

Haynes 25/188/230 /242/ HR120 / 718 /C-276/C-2000/B/ N/ S/ 625 / 617 / 718 / X/ N/ C/ G-30

ABOUT US

Why Choose Us?

Steel Factory

The company has multiple warehouses with sufficient stock of products of common specifications and grades.

Industry Group

The products are widely used in many important fields such as automobile, petroleum, railway, bridge, construction, electric power, transportation, machinery, shipbuilding, light industry, household appliances and kitchen.

Highly Customizable

We can provide various standard and non-standard specifications according to customer requirements. All our products are strictly in line with international standards.

Experience

The company has a professional technology research and development department, complete product production chain and technology, to ensure product quality and supply.

Factory Strength

Application Field

The stainless steel and alloy materials we produce are all made of high-quality raw materials, which have been carefully processed and produced to ensure the quality and performance of the products. Our stainless steel materials have the characteristics of high strength, corrosion resistance and beauty, and can be widely used in kitchen utensils, architectural decoration, chemical equipment and other fields; while our alloy materials have the characteristics of high strength, good high temperature performance and wear resistance, which can be Widely used in aviation, automobile, electronics and other fields.

Steel factory quality assurance certificate

Our company specializes in the production of a diverse range of high-quality stainless steel and alloy materials that cater to the specific needs of our clients. Our stainless steel materials come in a variety of specifications and models, including the widely used 304, 316, and 321, which can be further customized to meet the unique requirements of our customers. Additionally, our alloy materials are available in an array of types, such as titanium alloys, nickel alloys, and tungsten alloys, which are renowned for their exceptional properties and versatility. With our advanced production technology and strict quality control, we ensure that our materials meet the highest industry standards, delivering top-notch performance and reliability.

The raw material of stainless steel is an alloy material with corrosion resistance. The main components are iron, chromium, nickel and other elements. It has excellent corrosion resistance, high temperature resistance, oxidation resistance, and wear resistance.

Stainless steel raw materials are widely used in chemical, food, medical, aviation, construction and other fields. For example, the production of chemical equipment, food processing equipment, medical equipment, aero-engine components, building structures, etc.

Inconel alloy is a high-temperature alloy material. Its main components are nickel, chromium, molybdenum, iron and other elements. It has good corrosion resistance and high-temperature strength, and can be used for manufacturing in high-temperature environments.

Inconel alloy and stainless steel raw materials are very different in chemical composition and performance. Inconel alloy has better high temperature strength and corrosion resistance, and is suitable for use in high temperature and strong corrosion environments; while stainless steel raw materials are more suitable for use in normal temperature and normal pressure environments.

Hastelloy is a high-hardness alloy material. Its main components are cobalt, chromium, tungsten, carbon and other elements. It has good wear resistance and high hardness, and can be used to manufacture cutting tools.

There are great differences in chemical composition and performance between Hastelloy alloy, Inconel alloy and stainless steel raw materials. Hastelloy has better wear resistance and high hardness, and is suitable for manufacturing cutting tools; while Inconel alloy is suitable for use in high temperature and strong corrosion environments, stainless steel raw materialsIt is more suitable for use under normal temperature and normal pressure environment, and has good corrosion resistance.